- What Is an Engine Cylinder Head?

- Complex but Essential Part of Any Engine: Main Functions of the Engine Head

- Key Components of an Internal Combustion Engine Head

- Common Types of Engine Cylinder Heads

- Signs of a Damaged or Failing Engine Head

- Importance of the Head Gasket

- Maintenance as Part of Any Internal Combustion Cylinder Heads Care

- Engine Head in Modern vs. Older Cars

- Final Thoughts

What Is an Engine Cylinder Head?

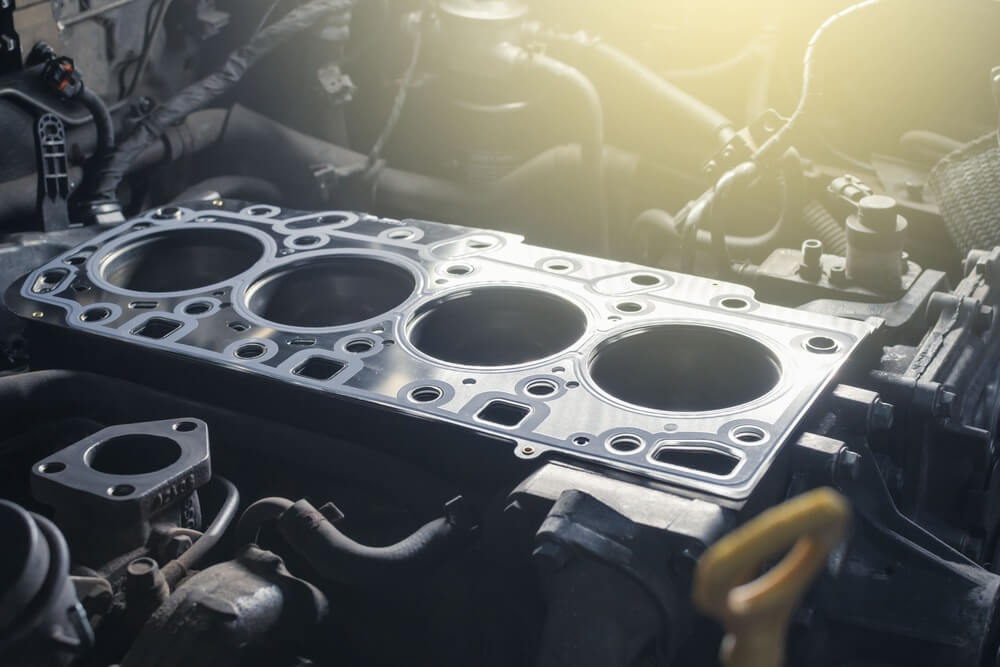

The engine head or cylinder head (or engine cylinder head) is a vital engine component located at the top of the engine block in any internal combustion engine. This engine part sits directly above the cylinders in the engine block, effectively sealing off the top of each cylinder to form the combustion chamber. The primary purpose of the engine head is to provide a seal over the cylinders. This is why it is called the “head” or “cylinder head.” Its primary function is to seal snugly the engine block, creating a sealed space where the fuel-air mixture combusts and drives the pistons.

The cylinder head is more than a cover for the engine; it is an advanced assembly that includes a substantial number of significant parts of the engine valve train and cooling system. As it interfaces directly with the engine block, the head and the engine block must be closely fitted, using a head gasket to maintain a seal tight enough so that no leakage of combustion gases, oil, or coolant takes place. The engine head is an important part that maintains the compression of the engine and performance in general.

Complex but Essential Part of Any Engine: Main Functions of the Engine Head

The engine cylinder head has several significant functions that are essential to the operation and efficiency of an internal combustion engine:

- Sealing the Combustion Chamber. Arguably the most significant of the engine head functions is to form an airtight seal for the combustion chamber. Working in combination with the head gasket, the cylinder head seals the seal between the head and the engine block. This seal holds combustion gases, coolant, and oil leakage, which is essential in providing maximum operating compression. If this seal did not exist, the engine would be wearing down in power, while oil or coolant would seep into the combustion chamber to cause severe engine damage.

- Supporting the Valve Train. The exhaust and intake valves are housed in the cylinder head and open and close to control the passage of exhaust gases and air into and out of the combustion chamber. The valves are critical to the engine’s breathing. The camshaft, located within the cylinder head in overhead camshaft designs, controls the timing and motion of these valves. Lobes of the camshaft press against rocker arms or lifters to drive the valves open, and springs return the valves to the closed position.

- Cooling and Lubrication. The engine head contains intricate coolant passages and oil passages that allow coolant and oil to circulate through the top of the engine. Cylinder head passages dissipate combustion heat generated to prevent the engine from overheating. Coolant carries heat to the radiator, and oil lubricates moving parts such as the rocker arms, valve stems, and camshaft lobes to reduce friction and wear.

- Compression and Ignition. The cylinder head’s design and shape indirectly specify the combustion chamber’s volume and shape, affecting the engine’s compression ratio and efficiency of combustion. The spark plugs or fuel injectors within the cylinder head ignite or inject the fuel-air mixture, initiating combustion that drives the piston downward to produce power.

Key Components of an Internal Combustion Engine Head

Understanding the various components stored within the engine cylinder head makes one appreciate how complicated it is:

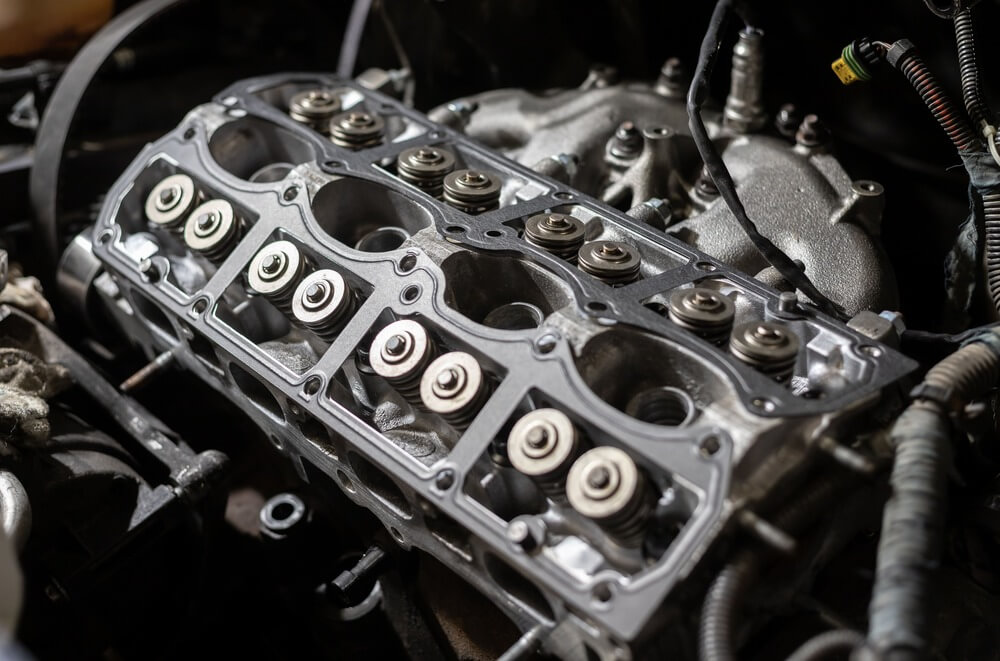

Valves (Intake and Exhaust)

Exhaust and intake valves control the supply of air and fuel into the combustion chamber and the evacuation of exhaust gases. Valve seats are highly precise machined surfaces in the cylinder head that, when they close the valves, provide a tight seal. Precise valve location and timing are essential to proper engine breathing and efficiency.

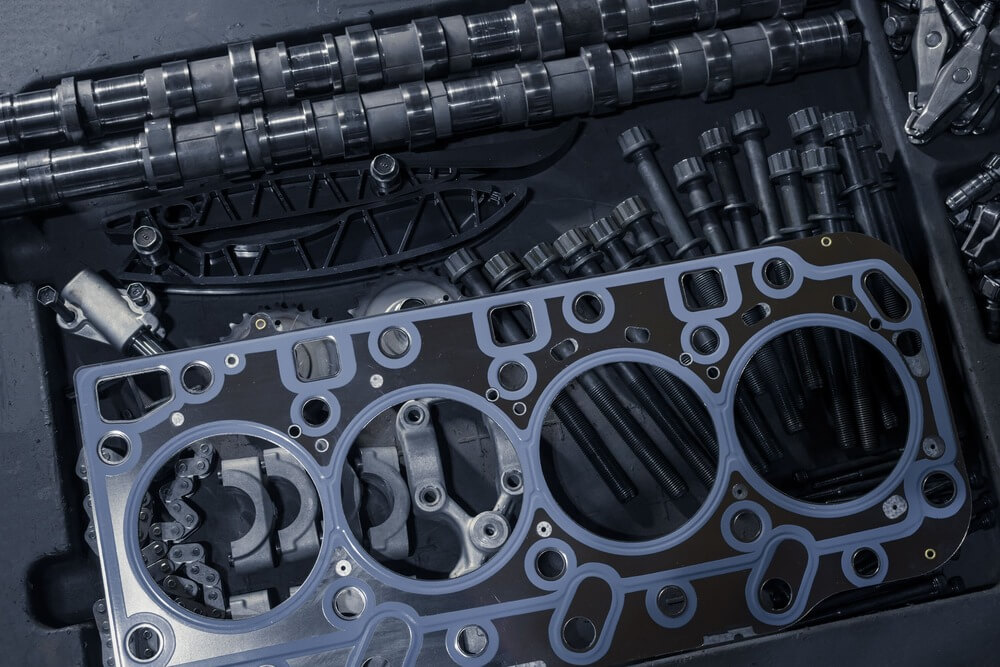

Camshaft

The camshaft is a rotating shaft with lobes which push against rocker arms or lifters to rotate the valves at the proper time of the engine cycle. Depending on the engines, the camshaft may be located within the cylinder head (overhead camshaft designs) or within the engine block (pushrod engines).

Rocker Arms and Pushrods

Pushrods and rocker arms in other engines, usually less sophisticated or older engines, transfer the motion of the camshaft within the engine block to the cylinder head valves. The two parts are what open and close the valves efficiently.

Spark Plugs or Fuel Injectors

In gasoline engine spark plugs, the air-fuel mixture is burned, while in diesel engines, fuel injectors inject fuel into the combustion chamber directly. Both are an essential component of ignition and are held firmly in place in the cylinder head.

Coolant Channels and Oil Passages

Coolant passages within the cylinder head allow coolant flow and heat absorption, while oil passages lubricate the moving parts within the valve train. These systems regulate engine temperature and prevent overheating or mechanical breakdown.

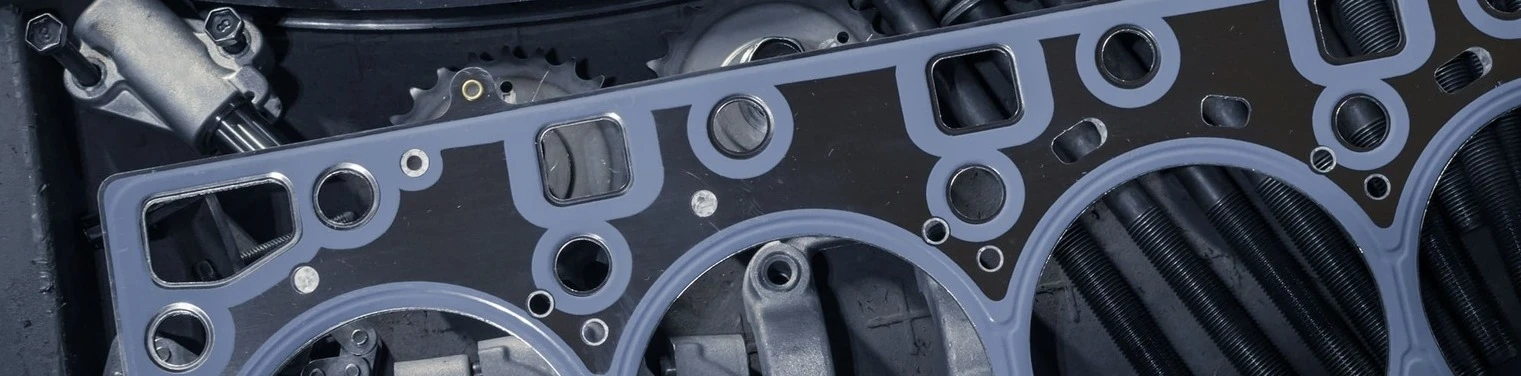

Gaskets (Head Gasket)

The head gasket closes the contact surface between engine block and cylinder head and prevents any fluid and gas leaks. It must withstand high pressure and temperature, so it’s one of the most significant components as far as engine reliability is concerned.

Common Types of Engine Cylinder Heads

Different engine heads are designed to be best at performance, durability, and production cost:

Single Overhead Camshaft (SOHC)

The SOHC design features a single camshaft per cylinder bank to drive intake as well as exhaust valves. The design represents an excellent balance of simplicity, reliability, and performance.

Dual Overhead Camshaft (DOHC)

The DOHC design features two camshafts per cylinder bank with separate control of intake and exhaust valves. The design improves valve control, increases engine speeds, and offers superior efficient airflow for performance.

Flathead / L-head

A previous design in which valves are positioned beside cylinders in the engine block rather than in the head. The model is easier to make but has poorer airflow and combustion.

Hemispherical (Hemi Head)

The Hemi head has a shaped-in combustion chamber that offers improved airflow and better combustion. It is typically used in performance engines since it is efficient but may be harder to make.

Signs of a Damaged or Failing Engine Head

Recognition of the indications of engine head failure helps to avoid catastrophic engine failure:

- Engine overheating: Generally caused by clogged coolant passages or twisted heads that restrict heat dissipation.

- Loss of compression: Leads to loss of power and poor engine performance.

- White exhaust smoke: Indicates coolant leakage into the combustion chamber because combustion gases combine with coolant.

- Oil contamination with coolant or vice versa: Results in milky fluids, which shows gasket leak or cracks.

- Coolant leakage: Visible near head gasket or cylinder head, meaning a seal rupture.

Importance of the Head Gasket

The head gasket is a flexible but thin gasket that seals the joint between the engine block and the cylinder head. Its failure is a serious flaw that causes:

- Leakage of combustion gases into the coolant system

- Mixing of oil and coolant, contaminating both fluids

- Loss of compression, reducing engine efficiency

- Overheating, potentially warping the cylinder head

Preventing the engine from overheating through maintenance and the replacement of the head gasket when needed is essential. Although replacement of a head gasket is expensive in terms of labor and materials, it is worth it to promote engine durability.

Cost of Head Gasket Replacement

Replacing a head gasket is one of the more costly engine repairs due to the labor-intensive nature of the job, which often involves disassembling significant portions of the engine. In Dubai, costs can vary based on the vehicle make, model, engine type, and the workshop’s rates. Labor charges in the UAE tend to be higher compared to many other regions due to skilled technician availability and operational costs.

As of recent estimates (note that prices fluctuate with market conditions, parts availability, and inflation; always get a personalized quote from a certified mechanic):

- For a standard passenger car (e.g., Toyota Camry or similar sedan), head gasket replacement typically ranges from AED 5,000 to AED 10,000 (approximately USD 1,360 to USD 2,720). This includes parts like the gasket itself (around AED 500–1,000) and labor (AED 4,000–8,000 for 20–40 hours of work).

- For luxury or high-performance vehicles (e.g., BMW or Mercedes-Benz), costs can escalate to AED 8,000 to AED 15,000 or more (USD 2,180 to USD 4,080+), depending on the complexity and the need for specialized tools or imported parts.

- Diesel engines or larger vehicles (e.g., SUVs like Toyota Prado) may cost AED 7,000 to AED 12,000 (USD 1,910 to USD 3,270), as they often have more cylinders and require additional work.

These figures are approximate and exclude additional repairs that might be discovered during the process, such as resurfacing the cylinder head or replacing damaged components. It’s advisable to consult multiple workshops for quotes and check for warranties on parts and labor.

Maintenance as Part of Any Internal Combustion Cylinder Heads Care

To keep the engine head strong and in working condition, attempt these maintenance tips:

- Monitor coolant levels regularly and make sure the radiator and cooling system are functioning well to prevent overheating.

- Use good quality engine oil to ensure the valve train and mobile components of the cylinder head remain adequately lubricated.

- Replace the head gasket and thermostat according to specifications or on first sign of wear.

- Monitor the engine temperature gauge regularly and address immediately if there’s any indication of overheating.

There is adequate prevention of warp and other cylinder head damage, which protects the engine from malfunction.

Engine Head in Modern vs. Older Cars

Modern automobile engines have dramatically evolved in their cylinder head designs:

- New heads often use thin aluminum alloys, improving heat transfer and reducing overall engine weight.

- Contemporary designs such as DOHC with variable valve timing allow greater control of valves and higher engine speeds, leading to greater efficiency and emissions.

- Less contemporary engines tend to employ cast iron heads with more primitive valve trains via pushrods and rocker arms, which are tougher but less efficient.

- While new heads yield better performance and fuel mileage, they add to the complexity and cost of maintenance.

Final Thoughts

The engine head is a technically advanced but essential part of any internal combustion engine. It is mounted on top of the engine block and holds the intake and exhaust valves, spark plugs, and critical passages for coolant and oil. It serves an important purpose in sealing the combustion chamber, controlling airflow, and maintaining compression and engine heat.

Maintaining the head gasket and engine head in proper working condition will help prevent leaks, overheat, and engine breakdown. For newer or older models, cylinder head condition and design will have immediate impacts on your vehicle’s performance, longevity, and durability. Regular maintenance and prompt repairs will ensure that your engine is smooth and reliable for years to come.